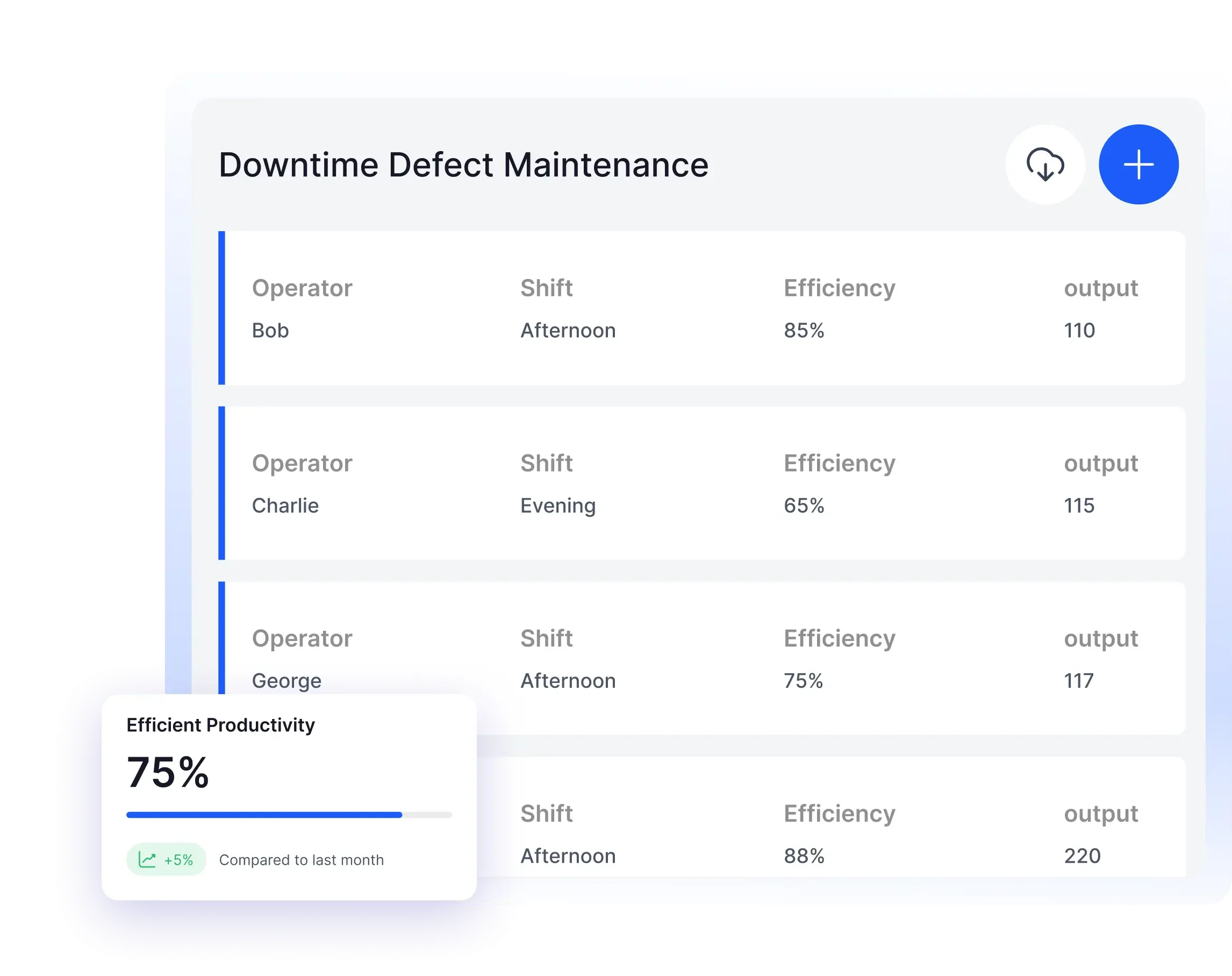

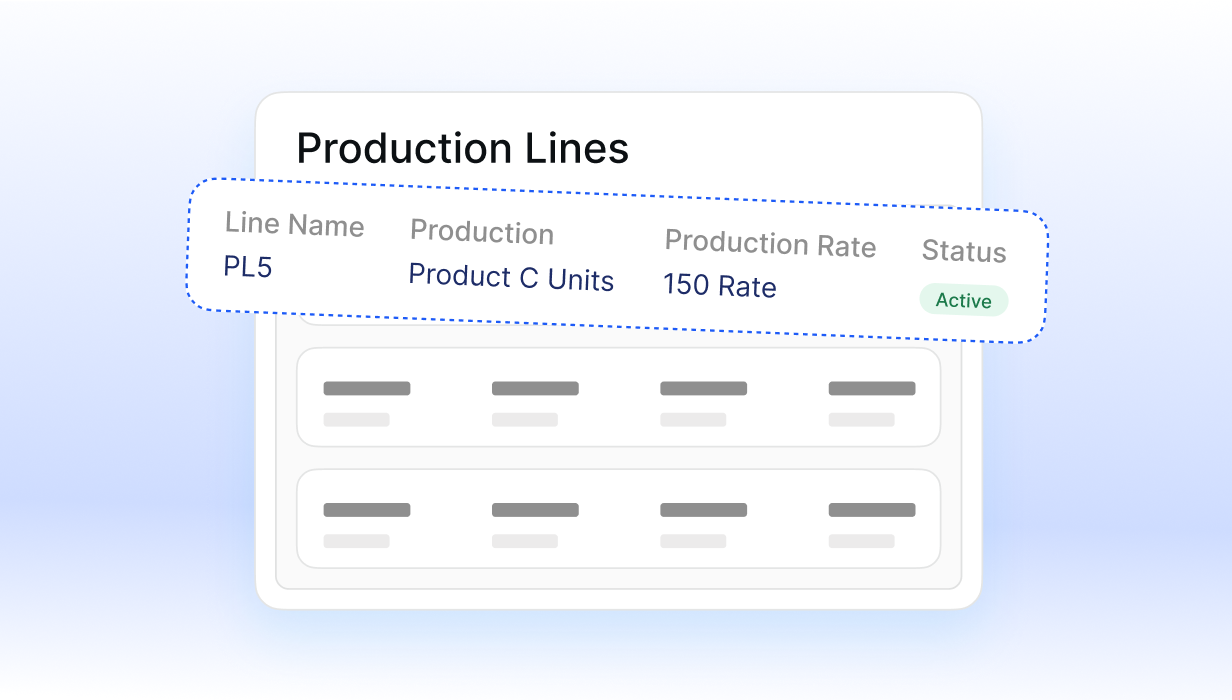

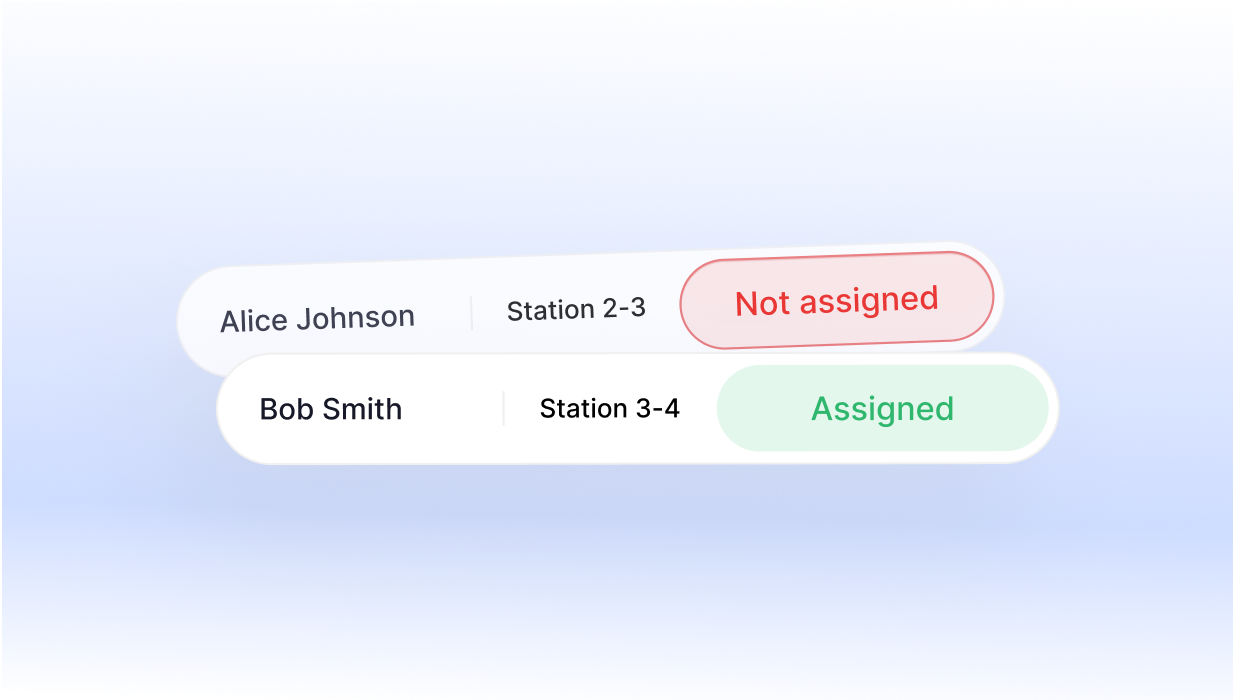

Manage your entire process with a complete view of all resources, from machine performance to staff KPIs.

Your production data is fragmented, leaving you in the dark about what’s really happening on your plant floor.

Our platform provides the real-time visibility and control you need to optimize your entire operation.

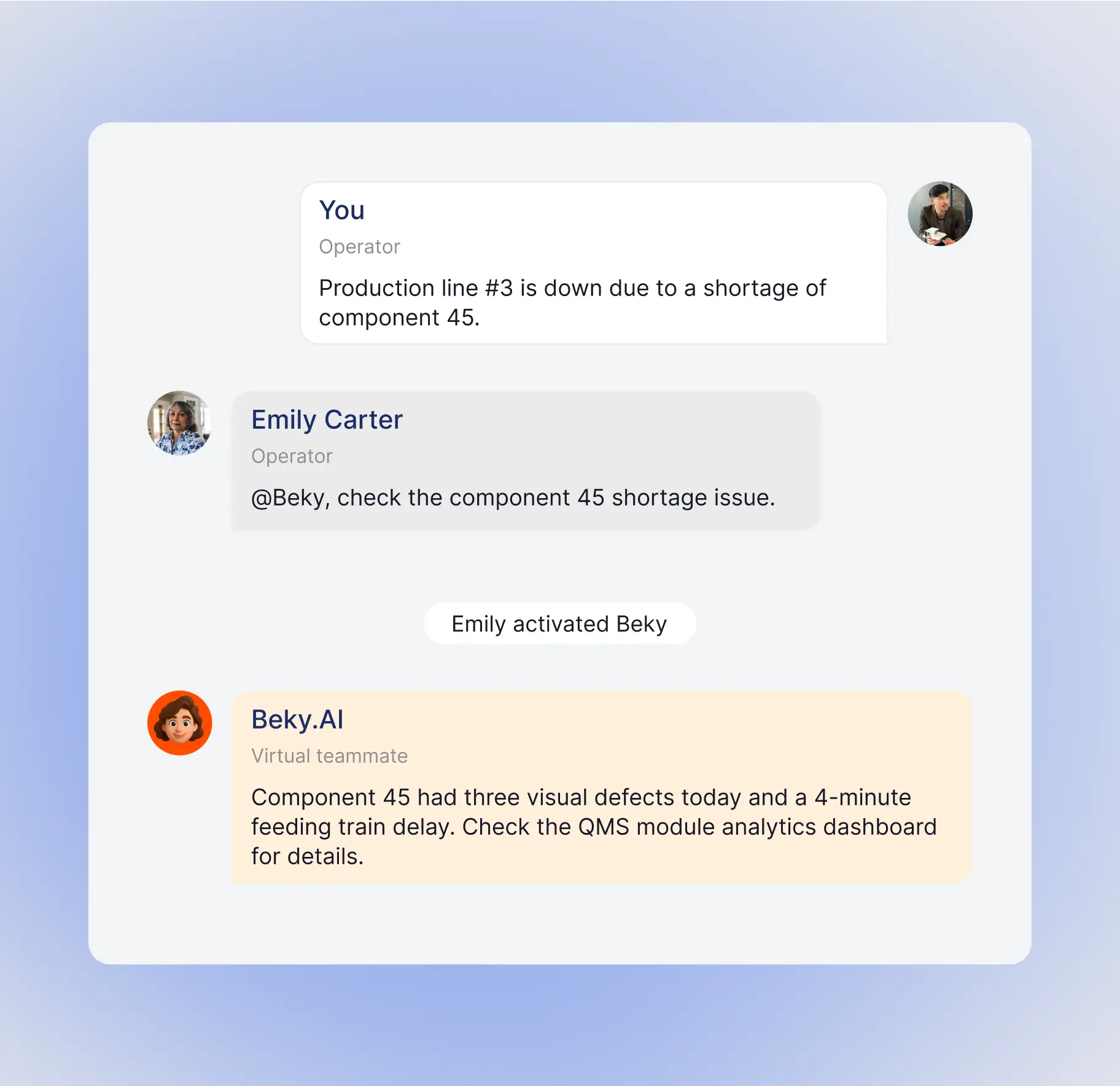

Your AI Assistant for Instant Insights

Trusted by Manufacturers Worldwide

Frequently Asked Questions

Can’t find the answer to your question here? Leave us a message!

We ensure a smooth launch in just 5 to 8 weeks through a phased approach that includes a manufacturing assessment, system configuration, pilot line testing, and comprehensive team training.

Our support doesn’t end after launch. You get direct email and phone access to our engineers for production issues and monthly optimization reviews to ensure your performance is always improving.

Most customers see significant results and a return on their investment in just 4 to 6 weeks, depending on the number of production lines you want to connect.

Disconnected systems force manual data transfer and create delays that cost you money. When Tobby integrates your production, quality, and logistics tools, all your data is shared in real-time, allowing all your systems to adjust immediately when a problem happens.

Tobby was built by manufacturing engineers with over 30 years of combined experience. We created our platform with a deep understanding of day-to-day plant operations, focusing on usability, powerful AI, and seamless integration to solve the real problems you face.

Yes. We have decades of experience building secure, high-performance platforms for a variety of industries. Tobby is engineered with best-in-class security protocols to ensure your data is always protected.

Book a 30-Minute demo to identify your biggest opportunities for improvement.